In the world of manufacturing companies, significant developments are underway in the automation of production lines. Seems like we are always in pursuit of improved efficiency, accuracy, and consistency nowadays. We employ advanced technologies to either replace or enhance human labor in this pursuit.

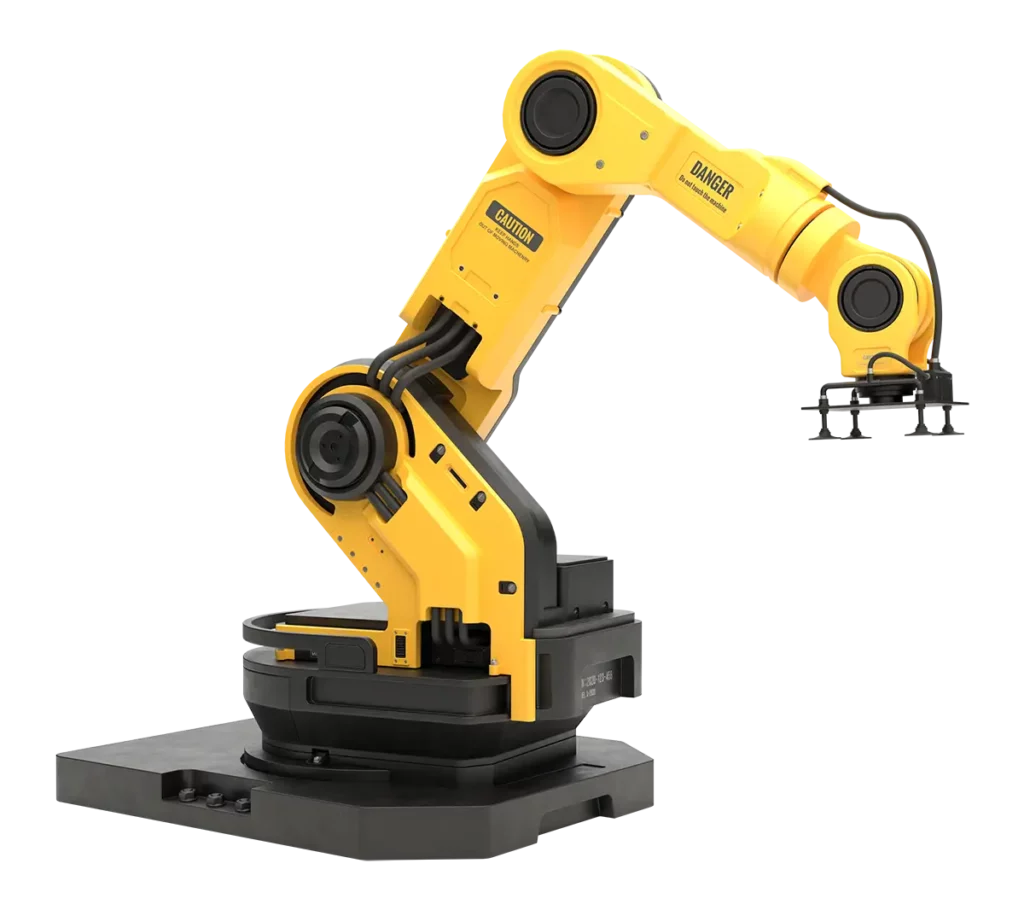

Robotic arms do more than wave. 😉

Robotic arms play a significant role in the automation of production lines. This also happens to be one of our specialties. These mechanical tools mimic human movements and perform tasks with tremendous precision and speed. They are equipped with sensors, actuators and control systems that enable precise and repeatable movements, even in complex manufacturing environments. Robot arms can be deployed in various ways for different processes, including assembly, packaging, welding, or inspection.

1. Precise

Automation of production lines minimizes the chance of inconsistencies and inaccuracies that often occur in manual processes. This has a direct impact on product quality and leads to less waste and rework.

2. Increased speed

Production line automation results in an increased production speed and shorter lead times, enabling companies to respond more quickly to the constantly changing market demand. Additionally, robotic arms can be operational 24/7 without getting tired, allowing the production line to run continuously. This leads to enhanced productivity and efficiency.

3. Flexibiliteit

The latest techniques in production line automation are programmable and adaptable. For example, robot arms can be quickly reprogrammed for various tasks and products, allowing production lines to be easily adjusted to changing demand and product variations.

4. Safety

Dangerous tasks can be entrusted to automated systems, thereby reducing the risk of workplace accidents and health hazards for employees. Automating dangerous tasks not only mitigates immediate risks but also contributes to a safer and healthier work environment and we consider it a crucial step toward prioritizing the well-being of employees and enhancing overall workplace safety.

5. Cost savings

The investment in automation yields even greater returns in the long term through cost savings resulting from lower labor expenses, reduced errors, and increased production efficiency. Moreover, you require fewer employees, which is especially beneficial during times of labor shortages.

6. Durability

Our solutions for production line automation are completely emission-free. They have a long lifespan and can be used for multiple purposes in the production line. Whenever possible, sustainable materials are used.

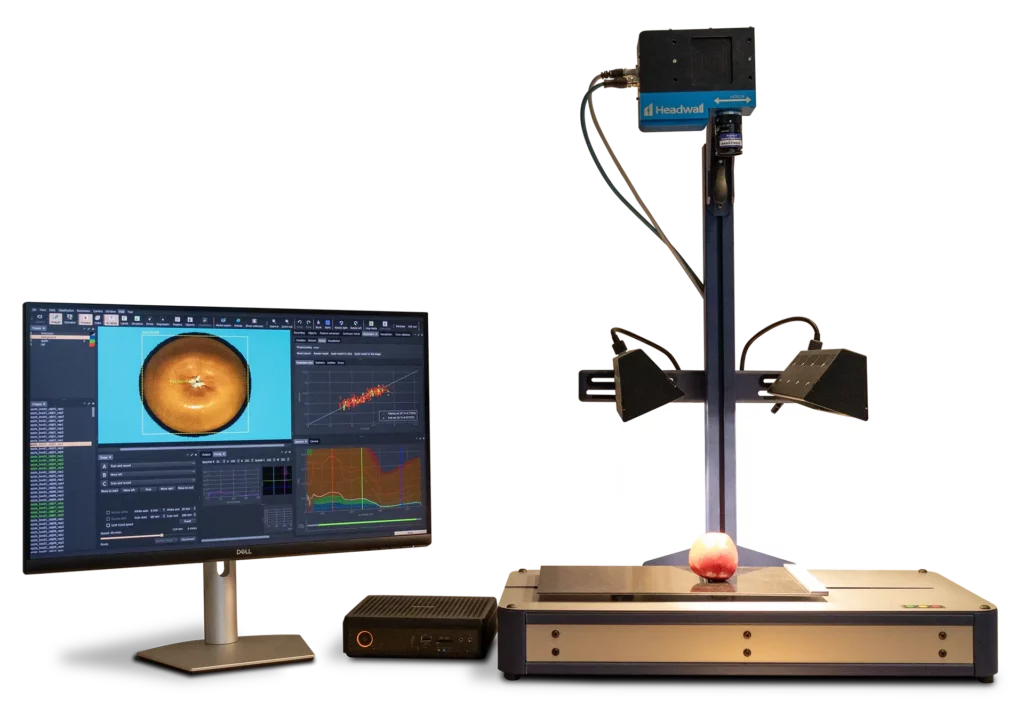

Furthermore, automating production lines allows for the capture and analysis of real-time data. This enables companies to gain insights into the performance of the production line and identify any bottlenecks or inefficiencies. As a result, they can make proactive decisions to further enhance processes.

Is your production line also in need of automation or improvement? We would be happy to brainstorm with you to find the right solution.

We deliver a total package, making it fun and easy for our clients to work with us. We are pragmatic and quick to deliver. Below, you find the most important areas of expertise we employ:

Click the expertise icons to learn more, or contact us directly!

Okay, we proudly share our stories, but we also back it up with evidence. Below, you can see some production lines that we have automated. You’ll find a selection of photos and videos for both learning and entertainment.

Your email address and personal information are 100% safe with us. It only takes a few seconds to sign up, and if you no longer wish to hear from us, unsubscribing is just as easy. We promise!